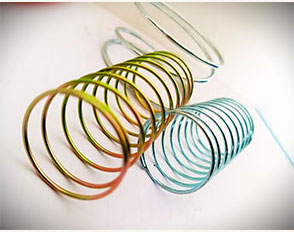

Compression Spring Manufacturers and Suppliers in India

Diligent Engineers, is a leading compression spring manufacturers and suppliers in India. We are providing the high quality of compression spring which is basically a helical spring designed to resist compressive forces, storing energy and when compressed and released it return it to its original length.

These are usually used in various kind of applications such as automotive suspension, medical devices and small applications as well. We have used strong quality of materials in these compression springs for increasing its durability structure and its versatility also for using them into all industrial sectors. Let’s check out our multiple types of compression springs, its using benefits and applications also!

Types of Compression Springs

Being the best compression spring manufacturers in India, we are providing the high-quality of compression rings which are made with precise engineering methods such as:

- Cylindrical Compression Springs: These are our most commonly and highly demanding springs and deliver consistent linear force in compact sizes. It makes a fundamental choice for various types of industrial sectors for various types of industries. With a uniform coil diameter, these springs are ideal for applications requiring predictable force and longevity. These are cost effective, reliable and it has equal force dimeter also.

- Conical Compression Springs: Our new designed conical compression springs gives a progressive force distribution and reduces the risk of bucking and ensuring optimal performance in applications where the reliable and variable force is required. This spring provides a superior and stable performance due to its tapered design. For getting more smooth type of transition, it has progressive force response and higher stability as well.

- Hourglass (Barrel) Compression Springs: The hourglass and barrel design of these compression springs gives a stable output for heavy weight and it feature a wider middle section with tampered types of ends. This compression spring ensures maximum force output in compact spaces and prevents any lateral shifting and highly preferable for high-force applications.

- Heavy Compression Springs: These heavy-duty compression springs are used for handling heavy load and applied in the large industrial settings. We have used high quality of materials in these heavy compression springs such as stainless steel, aluminium and cast iron for maintaining its structural integrity. The involvement of advanced alloy development such as chrome,-silicon, Inconel and titanium alloys can enhances overall corrosion resistance.

Technical Specifications of Compression Spring

For more information about compression spring, we have mentioned below a technical sheet such as:

| Parameter | Cylindrical | Conical | Hourglass (Barrel) | Heavy Duty |

|---|---|---|---|---|

| Material | Stainless Steel, High Carbon Steel, Music Wire | Stainless Steel, Alloy Steel | Stainless Steel, Music Wire | Chrome Silicon, Inconel |

| Wire Diameter (mm) | 0.1 – 20 | 0.2 – 15 | 0.2 – 10 | 2 – 50 |

| Outer Diameter (mm) | 1 – 200 | 2 – 150 | 3 – 100 | 5 – 300 |

| Free Length (mm) | 5 – 500 | 5 – 300 | 10 – 400 | 10 – 1000 |

| Spring Rate (N/mm) | 0.1 – 500 | 0.2 – 400 | 0.5 – 300 | 5 – 2000 |

| Load Capacity (N) | 5 – 5000 | 10 – 3000 | 10 – 2000 | 100 – 50000 |

| Ends Type | Closed & Ground, Open Ends | Closed & Ground, Open Ends | Closed & Ground | Closed & Ground |

| Applications | Automotive, Aerospace, Machinery | Valves, Suspension, Electrical | Shock Absorption, Damping | Heavy Machinery, Railway |

Important Features of Compression Springs

As a leading compression spring manufacturers in India, these all springs are made with high quality of materials inside and gives best performance such as:

- High Elasticity & Energy Storage: These compression springs store mechanical energy efficiently for repeated use in various applications due to their higher elasticity and energy storage.

- Customizable Spring Rate & Stiffness: The higher customizable spring rates in these compression springs can be designed with specific load-bearing and deflection properties.

- Wide Material Range: We have used multiple types of high-quality materials in these compression springs such as stainless steel, music wire, alloy steel, phosphor bronze, and high-performance alloys like Inconel and titanium.

- Compact & Space-Efficient: These springs can be designed to fit tight spaces while maintaining functionality. The design of compression springs with compact spaces helps for using in small-scale applications as well.

- Variety of Shapes & Configurations: They come in multiple types of shapes and configurations such as conical, barrel-shaped, and variable-pitch designs for optimized performance.

Applications of Compression Springs

Our all types of newly designed compression springs are highly used in multiple types of industrial sectors and gives high performance such as:

- Automotive suspension systems and shock absorption mechanisms

- Ballpoint pens, mechanical pencils, and small push mechanisms

- Industrial machinery, equipment, and heavy-duty compression systems

- Medical devices, surgical tools, and diagnostic equipment components

- Aerospace landing gear, actuators, and structural load management

- Valve systems, fluid control mechanisms, and pressure regulation

- Electrical switches, circuit breakers, and connector assemblies

- Firearms recoil systems, trigger mechanisms, and bolt assemblies

- Construction tools, heavy equipment, and load-bearing applications

- Vibration dampening, shock absorption, and isolation mount systems

As a leading compression spring manufacturers and suppliers in India, we as Diligent Engineers are providing the high-quality of compression spring. These compression springs are made with strong quality of materials such as stainless steel, cast iron and aluminium for increasing its durability and ability to use them in any kind of large industrial sectors. The working mechanism and smoothness gives high performance. For more information, contact us today!