Torsion Spring Manufacturers in India and Suppliers in India

Diligent Engineers is a leading torsion Spring manufacturers and suppliers in India, are providing the best-quality of torsion spring. These torsion springs are mechanical devices that stores the energy by twisting and releases it as rotational forces and highly used in the applications that require angular movement such as hinges, hatches, and garage doors.

This spring is made up of wires that wound in a spiral shape and one end of the wire is attached to a stationary point, and the other end is attached to a rotating point. These torsion springs are valued for their high torque, durability, long lifespan, customizability, and versatility. Below, we have listed down its types, using benefits and applications also!

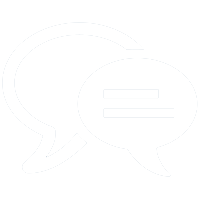

Types of Torsion Spring:

One of the leading torsion spring manufacturers in India, We are providing the high quality of torsion spring such as:

- Single Torsion Spring: These are our highly demanding and basic form of torsion spring and consist of a single coil that stores and releases rotational energy. It works by twisting around its axis when torque is applied and returning to its original position when the force is removed. The use of high-quality materials in these torsion springs helps for using them in hinges, clothespins, and garage doors.

- Double Torsion Spring: Our double torsion springs consist of two single torsion springs connected by a central bridge. The coils are wound in opposite directions, which provides balanced torque. The dual-coil system allows for a more even distribution of stress, increasing stability and durability. These springs provide more stable and controlled movement compared to single torsion springs. They are mainly applied in medical devices, agricultural equipment, and industrial machinery.

- Heavy Duty Torsion Springs: In these heavy-duty torsion springs, we have used strong and high-quality materials to improve their durability structure. They are designed for applications that require a significant amount of torque and durability. They are usually made with thicker wire and have a larger coil diameter. Our heavy-duty torsion springs are used in applications where strong torque resistance is needed to support heavy loads. We have used high-carbon steel, stainless steel, or coated alloys to prevent wear and corrosion.

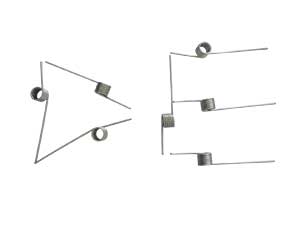

- Custom-Shaped Torsion Spring: As per industrial requirements, we provide custom-shaped torsion springs, and these are designed with unique shapes, such as rectangular or conical, to meet specific application needs. They can have custom ends for easy attachment. The design flexibility allows them to be adapted to non-standard or specialized mechanical systems. These springs have higher flexibility in design and functionality. It also ensures optimal performance in complex applications.

Technical Specifications of Torsion Spring

For more clarifications, we have mentioned below a technical sheet of Torsion Spring such as:

| Specification | Single Torsion Spring | Double Torsion Spring | Heavy Duty Torsion Spring | Custom-Shaped Torsion Spring |

|---|---|---|---|---|

| Material | Stainless Steel, Music Wire, Carbon Steel, Phosphor Bronze | Stainless Steel, Music Wire, Carbon Steel, Alloy Steel | High-Carbon Steel, Chrome-Silicon, Inconel | Depends on application (Stainless Steel, Alloy Steel, Titanium, etc.) |

| Wire Diameter Range | 0.2 mm – 6 mm | 0.3 mm – 8 mm | 1 mm – 12 mm | Customizable based on requirement |

| Coil Direction | Left-hand or Right-hand | Opposing Coils (Mirror Image) | Left-hand or Right-hand | Custom-configured |

| Leg Configuration | Straight, Hooked, Offset, Bent | Straight, Hooked, Extended Legs | Custom Heavy-duty Leg Design | Any custom shape or orientation |

| Torque Range | 0.01 Nm – 50 Nm | 0.05 Nm – 80 Nm | 10 Nm – 500 Nm | As per user specification |

| Maximum Load Capacity | 10 kg – 100 kg | 20 kg – 200 kg | 50 kg – 500 kg | Varies based on design |

| Spring Index | 4 – 12 | 5 – 15 | 4 – 10 | Application-based |

| Operating Temperature | -40°C to 250°C | -40°C to 300°C | -50°C to 400°C | Custom based on material |

| Surface Treatment | Zinc Plating, Black Oxide, Powder Coating | Zinc Plating, Electropolishing, Black Oxide | Shot Peening, Powder Coating, Electroplating | Customized Finishing Options |

Features of Torsion Spring

A top torsion spring suppliers in India, our all types of torsion spring are highly used in multiple types of industrial sectors due to its modern types of features such as:

| Feature | Benefit |

|---|---|

| High Torque Generation | Provides strong rotational force for various applications. |

| Compact Design | Enables space-efficient solutions in mechanical assemblies. |

| Customizable Configurations | Designed to meet unique application requirements in terms of coil direction, leg shape, and wire diameter. |

| Durable & High Fatigue Life | Withstands repeated use without significant loss of force, extending the lifespan of the product. |

| Wide Material Selection | Available in stainless steel, music wire, Inconel, and other alloys for different environments. |

| Corrosion & Wear Resistance | Surface treatments like zinc plating, black oxide, and powder coating enhance longevity. |

| Variable Deflection Angles | Supports up to 720° deflection in double torsion designs for maximum flexibility. |

| Temperature & Environmental Adaptability | Operates efficiently in extreme hot or cold conditions, suitable for aerospace and industrial uses. |

| Heavy Load Handling | Heavy-duty torsion springs support high-load applications such as industrial doors and military-grade machinery. |

Applications of our Torsion Spring

These all types of Torsion Spring are majorly used in multiple types of industrial sectors such as:

- Hinges & Door Mechanisms: These new mechanism of torsion springs has controlled rotation in heavy-duty doors, gates, and lid mechanisms.

- Automotive Suspension Systems: These are highly used in vehicle suspensions to absorb shocks and maintain stability.

- Clips & Clamps: The attached clips and clamps in these torsion springs help for secure holding in industrial and household applications.

- Robotic Arms & Grippers: This can enhance higher precision in movement and torque control for automated systems.

- Medical Instruments: These torsion springs are highly used in surgical tools and prosthetic devices for precise actuation.

- Aircraft Components: These are used in landing gear, control surfaces, and wing flaps for controlled movement.

- Retractable Seating & Furniture: The smooth mechanism of these torsion springs gives smooth folding and unfolding in chairs and tables.

- Agricultural Machinery: In agricultural machinery, it gives higher performance in heavy-duty farming equipment and tillers.

As a dominant torsion spring manufacturers and suppliers in India, we as Diligent Engineers are providing the high-quality of torsion spring. These new torsion springs are used in multiple types of industrial sectors due to its working mechanism. The use of new working mechanism in these springs helps for increasing its performance and applied in every kind of industrial sectors. For more information, contact us today!