- Flexibility in Design: As leading wire form manufacturers, our wire forms are designed to be flexible, allowing for a range of shapes and configurations to meet the unique needs of your application.

- Durable Construction: Robust construction is our main priority, and as a result, our wire forms are made to be long-lasting under harsh circumstances by absorbing stress and strain.

- Precision Bending and Forming: With the use of modern equipment, we being wire form suppliers guarantee precision wire bending and forming to produce wire forms with uniform shapes and dimensions.

Wire Form Manufacturers in Pune and Suppliers in Pune

Diligent Engineers is a leading wire form manufacturers in Pune and suppliers in Pune, is the place where precision and innovation combine.

As top wireform manufacturers, we take great satisfaction in offering premium products that are tailored to your applications particular requirements. Examine the specifics below to see how our wire form differs.

Product Information:

To ensure longevity and resilience to environmental variables, we being wire form suppliers provide our wire form that are created utilising a variety of materials,

such as stainless steel, music wire, or other alloys. Strict quality control procedures ensure that every wireform performs to the greatest possible requirements.

Characteristics:

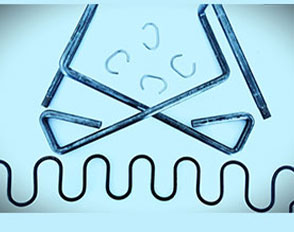

Configurations:

Our wire form comes in various configurations to cater to a wide range of applications

- Flat Wire forms: These wire forms are strong and stable, making them perfect for applications that call for a flat or planar shape.

- Round Wire forms: Round wireform offer flexibility and controlled spring back, making them ideal for applications requiring a circular or coiled shape.

- Custom Wire forms: Made to your exact specifications, custom wire forms are engineered to fit unusual shapes and arrangements.

Key Parameters:

- Wire Diameter: To satisfy the strength and flexibility requirements of your application, we as leading wire form manufacturers provide our wire forms that can be precisely customised with wire diameters.

- Bend Radius: To guarantee peak performance and avoid deformation, we meticulously regulate the bend radius of our wire forms.

- Material Selection: Being top wireform suppliers you may select the ideal blend of strength, flexibility, and corrosion resistance from our selection of materials for our wire forms.

Applications:

As leading wire form manufacturers, suppliers, a wide range of industries use our wireform, including:

- Automotive: Applied to a number of parts, including wire harnesses, braking systems, and seat mechanics.

- Electronics: Used in parts like electrical connections and other devices that need to be precisely shaped and supported.

- Medical Devices: Essential for applications like surgical tools and implanted devices where certain wire shapes are needed.

- Consumer goods: Used to provide support and function in products ranging from furnishings to appliances.

Select Diligent Engineers as your go-to wire form manufacturers, suppliers in Pune for unrivalled dependability, accuracy, and adaptability. Because of our constant dedication to quality, our wireforms both meet and surpass industry requirements, making them the ideal choice for your wide range of applications. Get in touch with us right now to talk about your wireform needs and discover what it means to collaborate with industry experts in precision engineering.

- In addition to manufacturing durable compression, extension, and torsion springs, we also produce custom Wire Forms and wire form springs for electronics, medical equipment manufacturers, and the appliance, aerospace, HVAC, automotive, construction, and agricultural industries.Our CNC manufacturing technology allows us to cost effectively develop prototypes of complex wire form parts.

- "Wire forms can be designed to provide forces in applications where a deflection or torsional force is needed using high carbon spring steel, or where support or structure is necessary using low carbon steel. Typical designs for wire forms include linkages, torsion bars/rods, and wires. Linkages are products that require the need for two or more details to connect and work together to manage forces and movement."