Tension Spring Manufacturers and Suppliers in India

Diligent Engineers is a former tension spring manufacturers and suppliers in India. We are providing the new mechanism of tension spring which is a mechanical device that is used for store and release energy by resisting stretching forces. It is made of coiled wire that expands when pulled apart and returns to its original shape when the force is removed.

These springs typically have hooks, loops, or other attachment ends to connect to different components in a system. The amount of force a tension spring exerts depends on its material, coil diameter, wire thickness, and design. Due to its mechanism, it is highly used in small scale industrial sectors to large one and gives higher performance.

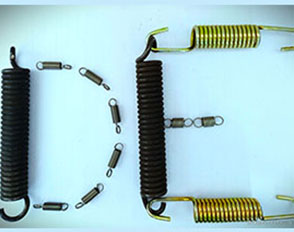

Types of Tension Spring

One of the former tension spring manufacturers in India, we are providing various types of tension spring and each one gives higher performance such as:

- Helical Tension Extension Spring: Helical tension extension springs are one of the most frequently used, with closely coiled springs, which store potential energy when they are extended. Most of these springs have hooks, loops, or other coupling devices on one end to couple with other machine and equipment assembly elements. The resistance control that is offered by these springs renders them most typically utilized in aerospace engineering applications, which utilize them for shock damping to regulate landing gear mechanisms and to retract them in a safe manner.

- Extended Tension Spring: Longer tension springs are engineered to work through a longer extension distance, generating force progressively and not a rapid return. It is a highly useful design in which smooth movement is needed. Longer tension springs in factory machinery keep tension in conveyor belt systems stable, jerk-free, and unbalance-free. Longer tension springs are applied in the building and construction sector in hydraulic systems for smooth and controlled movement of heavy equipment.

- Variable Rate Tension Spring: Variable rate tension springs have non-uniform spacing of coils, i.e., extension force is constantly changing rather than being constant. This makes it very suitable to be used in dynamic tension control-requiring applications. Variable rate springs employed in the suspension of vehicles give a smoother ride as they can adapt themselves to varying road conditions. The renewable energy industry also makes use of these springs, especially in wind turbine tensioning systems where they ensure accurate blade positioning under different wind speeds.

- Precision Micro Tension Spring: Precision micro tension springs are applied where extremely small tension forces with extremely high accuracy are required. Precision along with extremely small size is required by applications that employ them. It is utilized in minimally invasive surgical instruments in medicine technology where it records exact movement in fine procedures. Consumer electronics, i.e., micro-actuators and wearables, as well as consumer devices providing smooth mechanical movement in shrinking spaces, utilize micro tension springs.

Technical Specifications of Tension Spring

For detailed information, we have mentioned below a technical sheet such as:

| Specification | Helical Tension Extension | Extended Tension | Variable Rate Tension | Precision Micro Tension |

|---|---|---|---|---|

| Material | Steel, stainless steel, Inconel | High-tensile steel, phosphor bronze | Carbon composites, nano-infused steel | Superelastic alloys, titanium |

| Wire Diameter | 0.2 – 20 mm | 0.5 – 25 mm | 0.3 – 15 mm | 0.05 – 5 mm |

| Spring Rate | Constant | Gradual force buildup | Progressive, adaptive | Ultra-precise, micro-loads |

| Max Load Capacity | Up to 10,000 N | Up to 15,000 N | Adaptive, high durability | Up to 500 N |

| Corrosion Resistance | Standard or coated options | Enhanced coatings | High with advanced alloys | Ultra-high nano-coatings |

| Temperature Limit | Up to 300°C | Up to 500°C | Up to 600°C | Up to 250°C |

| Fatigue Resistance | High durability | Very high strength | Extreme for dynamic loads | Ultra-long life cycle |

| Smart Technology | AI-based monitoring | IoT load tracking | Embedded stress sensors | MEMS integration |

| Key Applications | Automotive, aerospace, medical | Industrial, construction, fitness | Robotics, wind turbines, aerospace | Medical, electronics, satellites |

Important Features and Benefits of Tension Spring

Being the best Tension Spring suppliers in India, our all types of Tension Spring are highly used in multiple types of industries due to its various new features such as:

- Adjustable Load-Controlled High-Precise Performance: We have tension springs engineered with precise coil configurations that build up resistance control and optimize load distribution. It enables us to offer silky, stable performance for the aerospace, robotics, and medical industries where precision is a concern.

- Lightweight Efficiency and Durability with Advanced Materials: Our tension springs are made from highly strong materials such as titanium, Inconel, and carbon-fiber compounds that render them extremely strong yet extremely light in weight. It is used with specific intentions for use in vehicle suspension, production of solar energy from panels, utilization of wind power, air travel, and sporting goods whose lightness requires the creation of higher efficiency.

- Intelligent Integration towards Optimum Real-Time Performance: With the coming IoT and smart sensor technology, our springs have real-time sensing devices to monitor stress, load cycles, and fatigue. Our smart tension springs are used safest in aerospace actuation, industrial automation, and precision medical implantation, where prevention from premature failure prevents catastrophic failure.

- Industry Specification Customization Differentiation: We understand that every company has different requirements, and we offer completely customized tension springs with different coil pitch, force limit, and fastening. We manufacture springs on order with better performance from robotic prosthetic limbs to space missions.

Applications of Tension Spring

These all types of tension spring are majorly used in multiple types of industrial sectors such as:

- Aerospace landing gear and shock absorption systems

- Automotive brake, throttle, and suspension control

- Industrial conveyor belt and machinery tensioning systems

- Medical robotic surgical tools and precision instruments

- Renewable energy wind turbine blade tensioning

- Sports equipment resistance and gym machine systems

- Precision micro-actuators in compact electronic devices

- Construction hydraulic support and controlled lifting mechanisms

- Satellite antenna deployment and space exploration systems

- Advanced robotics for movement balance and force control

As a former tension spring manufacturers and suppliers in India, we as Diligent Engineers are providing the high-quality of tension spring. These tension spring has store and release mechanism and it used in large industrial sectors for completing major and complex tasks. We have used strong and pure form of material in these tension spring for increasing its durability structure and resist corrosion. With advancements in smart materials, IoT integration, and high-strength alloys, our modern tension springs are becoming more durable, adaptive, and efficient across a wide range of applications. For more information, contact us today!