- Precision Engineering: Being top torsion spring suppliers, our products are designed to deliver constant torque and angular deflection, our precision-engineered torsion springs are appropriate for applications requiring a certain amount of rotation.

- High-Tensile Strength: As leading torsion spring manufacturers our torsion springs are robust even in challenging conditions because of their high tensile strength and capacity to support heavy loads.

- Corrosion Resistance: Our torsion springs can tolerate a range of circumstances and are resistant to corrosion.

Torsion Spring Manufacturers in Pune and Suppliers in Pune

Diligent Engineers a leading torsion spring manufacturers, suppliers in Pune where innovation and excellence coexist. Being a top producer of torsion springs, we take pride in offering innovative products that redefine dependability. Explore the specifics below to see what makes our torsion springs unique.

What exactly are Torsion Springs

As leading torsion spring manufacturers, our torsion springs are built to last and resist wear since they are composed of premium materials like piano wire, stainless steel, or alloy steel.

Every torsion spring we manufacture is guaranteed to function consistently and dependably thanks to our stringent testing procedures.

Characteristics:

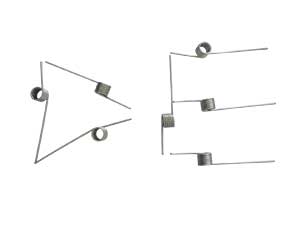

Configurations:

Being a top torsion spring suppliers, our torsion springs are available in various configurations to meet diverse industry needs:

- Single Torsion Springs: For applications requiring straightforward torque solutions, single torsion springs are the perfect choice since they are compact and long-lasting.

- Double Torsion Springs: For applications requiring rotational force in both directions, double torsion springs are adaptable and offer balanced torque.

- Straight Offset Torsion Springs: Providing precise torque in a small package, straight offset torsion springs are perfect for applications with limited space.

Key Parameters:

- Angular Deflection: For superior performance in rotating applications, we as leading torsion springs manufacturers provide our torsion springs with precise angular deflection.

- Wire Diameter and Leg Length: By carefully adjusting the wire diameter and leg length, tension springs may be made to precisely match certain torque and rotational requirements.

- Surface Finish: Being a top torsion spring suppliers, the thoughtful surface treatment applied to our torsion springs improves their longevity and resistance to corrosion.

Applications:

As leading torsion spring manufacturers, suppliers our torsion springs are used in a wide range of industries, such as:

- Automotive: Found in a number of parts, including steering systems, trunk lids, and door hinges.

- Electronics: Used in components and retractable antennas, among other devices that need rotating force.

- Industrial Equipment: Applied to machinery and apparatus where precise rotation is essential to operation.

- Medical Devices: Essential for applications requiring exact rotating force, such as surgical tools.

Select Diligent Engineers as your torsion spring manufacturers, suppliers in Pune for unmatched precision, reliability, and quality. Our commitment to quality ensures that our torsion springs are the ideal option for rotational applications, meeting and beyond industry requirements. Get in touch with us right now to talk about your needs for torsion springs and learn what it means to work with professionals in precision engineering.

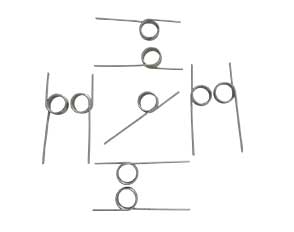

- Torsion Springs are helical springs that exert a torque or rotary force. The ends of torsion springs are attached to other components, and when those components rotate around the center of the spring,

- The spring tries to push them back to their original position.

- The coil twists into a tighter spiral and pulls back against the applied force when force is applied to the ends. The springs found in utility trailers and vehicle doors are typical examples.

- Torsion spring production typically uses coiling or shaping machinery like extension springs.